Cooling towers, also known as heat rejection devices, are systems that remove heat from fluids like water, in order to provide cool fluids to controlled environments. Cooling towers are typically used to cool down water or other fluids that have been heated during an industrial manufacturing process or some similar process. Read More…

Our circular FRP (fiberglass reinforced polyester) cooling towers are second to none. With five different models in production- one to meet every need for businesses of all sizes. We are the oldest, full-service fiberglass water cooling tower manufacturer in business today. We bring only the highest quality of customer service to our valued clients. When it comes to FRP cooling towers we bring...

As a leader in the industry, we have become competitive in all types of cooling tower projects of any size and design. We are constantly developing newer methods to serve the growing needs in the industry, and our efforts have led us to become a highly competitive, full-service engineering, design, and repair contractor. Our emphasis on performance and low maintenance continues to give STAR the...

Since 2004 Composite Cooling Solutions (CCS) has been a supplier for cooling tower solutions. Though CCS was officially created in 2004, our staffs experience in the field goes back over a century and a half. We specialize in creating concrete cooling towers with both counterflow and crossflow configurations. With our extensive background in the industry and our growing number of cooling tower...

At Cold Shot Chillers, we create a number of chilling systems, including cooling towers. Our products are designed for durability and cost effectiveness. Our engineers can easily custom build any machine to fit the needs of a particular application.

More Cooling Tower Manufacturers

Cooling towers, also called heat rejection devices, are systems designed to remove heat from fluids, such as water, providing cooled fluids to controlled environments. They are commonly used to cool down water or other fluids that have been heated during industrial manufacturing or similar processes.

Applications

Cooling towers are extensively used across various industries due to their ability to efficiently dissipate heat and regulate temperatures. A primary application is in power plants, where they are essential for cooling the hot water used in electricity generation. By providing a continuous flow of cooled water, cooling towers ensure optimal performance and efficiency of power generation systems.

In commercial and industrial buildings, cooling towers are integral to HVAC systems, helping to regulate indoor temperatures and ensure comfortable working environments for occupants in large buildings, factories, and shopping malls. They remove excess heat from air conditioning units, contributing to better indoor air quality and energy efficiency, and reducing overall electricity consumption.

The manufacturing sector heavily relies on cooling towers to maintain equipment and process temperatures within specific operational limits. Industries such as metal processing, plastic molding, and chemical production benefit from cooling towers’ ability to dissipate excess heat generated during manufacturing processes, safeguarding machinery and enhancing productivity.

In the oil refining industry, cooling towers are essential for cooling hydrocarbons during the refining process, ensuring product quality and efficiency in this critical sector.

Cooling towers also play a vital role in data centers, where they help regulate the temperature of computer systems and servers. By preventing overheating, cooling towers safeguard the continuous and reliable operation of data center facilities.

In summary, cooling towers have diverse applications, including power generation, manufacturing, HVAC systems, oil refining, and data centers. Their versatility and efficiency in heat dissipation make them indispensable in a wide array of industries, contributing to enhanced productivity, energy efficiency, and environmental sustainability.

History

The concept of tower cooling has been utilized since ancient times. Civilizations such as those in Rome, Greece, the Middle East, and the Americas used water to evaporate heat and provide relief from high temperatures. For instance, some placed porous water jugs in their windows, where the water would capture the heat, allowing cooled air to pass through.

Thus, the idea of air conditioning is quite old. However, it wasn’t until the Industrial Revolution that people began to manipulate the concept mechanically. In 1819, William Warrel and Robert Salmon received a British patent for their “evaporative cooler,” designed to cool air generally. In 1840, French physicist Jean Claude Eugène Péclet created an early version of a modern evaporative cooler, initially used as an evaporative condenser for steam engines.

Despite these early efforts, cooling towers did not become truly viable until the early 20th century. American inventors began rapidly patenting various versions of the cooling tower, describing them in diverse ways, such as drip coolers, wet boxes, swamp coolers, and desert coolers.

The first modern cooling towers employed direct cooling with tools like fans, sprayers, nozzles, and troughs. Over time, these were replaced by motorized fans, circulating pumps, and similar apparatus. Today, cooling towers come in a variety of configurations.

How It Works

Cooling towers operate based on the principle of evaporative cooling, utilizing the thermodynamic properties of water to remove excess heat from industrial processes or HVAC systems. The process starts with hot water being pumped from the industrial equipment or air conditioning system into the cooling tower. Inside, the hot water is distributed over a series of fill materials designed to increase the exposed surface area, enhancing the interaction between the water and the air flowing through the tower.

Large fans at the base or top of the cooling tower draw in ambient air, which then comes into direct contact with the water-saturated fill material. A small fraction of the hot water evaporates upon contact, transitioning from a liquid to a vapor state. This phase change requires energy, which is absorbed from the remaining water, significantly lowering its temperature.

The cooled water collects in the bottom basin of the cooling tower and is recirculated back to the industrial process or HVAC system, where it absorbs more heat, continuing the cooling cycle. This recirculation allows for continuous and efficient cooling operation.

To maintain optimal performance and prevent mineral buildup, a portion of the water, known as “blowdown,” is periodically purged and replaced with fresh makeup water. This helps maintain the chemical balance and prevents excessive mineral concentration.

Evaporative cooling in cooling towers is highly effective and energy-efficient, making them a preferred choice for various industrial applications. Their ability to efficiently dissipate heat into the atmosphere or recycle it for reuse makes cooling towers essential components in power plants, manufacturing processes, oil refineries, and large-scale HVAC systems, contributing to energy conservation and environmental sustainability.

Types

Cooling towers come in several main types: open loop towers, closed loop towers, counter-flow systems, and cross flow systems. Additional types include HVAC cooling towers, industrial cooling towers, evaporative cooling towers, water cooling towers, and chiller cooling towers.

Open loop towers, also known as open circuit cooling towers, distribute water internally where it directly encounters cooling air. The air absorbs heat from the water and exits into the atmosphere, while the cooled water falls into a collection basin.

Closed loop tower systems prevent contact between the cooling agent and the liquid being cooled, allowing the liquid to be recirculated without contamination. This design means the coolant and the material being cooled don’t need to be compatible since they never come into contact.

Counter-flow tower systems operate with opposing air and water flows. Air moves upward, absorbing heat from the water as it flows downward.

Cross flow cooling towers function with perpendicular air and water flows, where air flows sideways and water flows downward.

HVAC cooling towers are typically found in large buildings, used to maintain comfortable interior temperatures.

Industrial cooling towers are more durable than HVAC units because they operate year-round and cool much larger volumes of liquid.

Evaporative and water cooling towers rely on evaporation to release heat into the atmosphere and require a local water source for efficiency, such as rivers, wells, seas, or lakes.

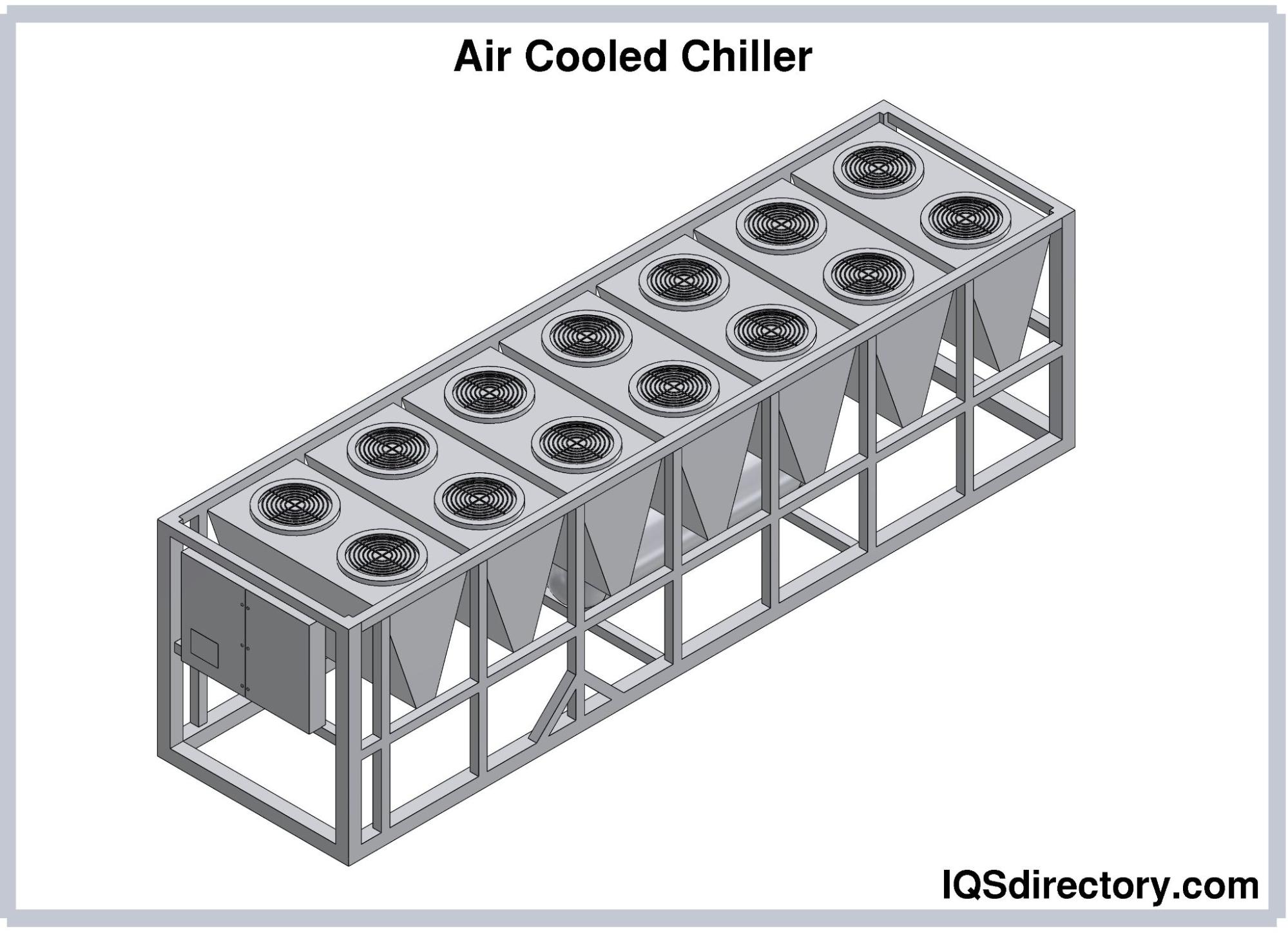

Chiller cooling towers include refrigerant components to cool fluid to even lower temperatures.

Equipment Components

Cooling towers generally comprise several key components, including a wet deck, air inlet and outlet ports, intake louvers, a cool water basin, a fill space, mechanical instrumentation, fans, drift eliminators, and a shell.

Wet decks, also called water distribution decks, feature a set of nozzles that spray water onto fill material to enhance heat transfer.

Air inlet and outlet ports serve as the entry and exit points for air within the tower.

Intake louvers help equalize the air flowing into the fill and retain water within the tower.

Cool water basins, located at the base of the tower, collect the cooled water after it has been discharged.

Fill space, made from PP or PVC in a corrugated or honeycomb pattern, is the main area where cool air extracts heat from hot water.

Mechanical instrumentation includes components such as driveshafts, gearboxes, fans, sensors, pumps, connectors, and cables, which ensure the system operates properly and efficiently.

Fans are crucial for cooling towers that lack a natural draft system. They not only enhance cooling but also help prevent the growth of bacteria, mildew, or mold by providing a level of drying. Fans can be axial or centrifugal and may be positioned overhead, within, or below the system.

Drift eliminators increase the efficiency and environmental friendliness of cooling towers by capturing water droplets in the air stream before they can escape as vapor.

Shells, or cases, enclose the system, holding the liquid until it recirculates. Made from materials such as galvanized steel, ceramic, chemically treated wood, reinforced plastic, or aluminum, shells also provide structural support for the tower’s internal components and fan system.

Benefits

Cooling towers provide numerous critical benefits, making them essential in various industrial processes and climate control systems. One of their main advantages is efficient heat dissipation, which prevents equipment overheating and ensures smooth and reliable operations in power plants, manufacturing facilities, and refineries. By effectively removing excess heat, cooling towers help maintain optimal temperatures, extending equipment lifespan and reducing the risk of costly breakdowns.

In commercial and industrial buildings, cooling towers play a crucial role in HVAC systems, contributing to comfortable indoor environments for occupants. They efficiently remove heat from air conditioning units, allowing the systems to provide pleasant temperatures and improve indoor air quality, which enhances productivity and well-being in work environments.

Another significant benefit of cooling towers is their energy efficiency. Utilizing the principles of evaporative cooling, they consume considerably less energy compared to traditional air-cooled systems. The evaporation process requires relatively low energy inputs, leading to cost savings and a reduced environmental impact, especially in energy-intensive industries.

Cooling towers also promote water conservation. By recirculating cooled water, they minimize overall water usage, which is particularly important in regions facing water scarcity. This recycling process not only reduces water consumption but also decreases the discharge of heated water into natural water bodies, mitigating thermal pollution and protecting aquatic ecosystems.

Furthermore, cooling towers contribute to sustainable practices by helping reduce carbon emissions. As energy-efficient cooling solutions, they assist industries in lowering their carbon footprint and moving towards more environmentally friendly operations.

In summary, the benefits of cooling towers include improved equipment performance, energy efficiency, water conservation, reduced environmental impact, and support for sustainable practices. These advantages highlight the indispensability of cooling towers in modern industrial processes, power generation, and climate control systems, playing a vital role in addressing the challenges of a rapidly evolving and environmentally conscious world.

Design and Customization

When designing cooling towers, manufacturers consider several crucial factors, including available space, water sources, electrical supply, materials, and structural capacity. Budget is also a key consideration, as the design of a cooling tower significantly impacts its cost and operational efficiency.

Suppliers can provide either standard or custom cooling towers based on your specifications. Custom cooling towers are ideal for meeting specific volume requirements and adapting to the environment in which they will be used. For instance, manufacturers often create custom cooling towers to address challenges such as piping, electrical sources, and capacity that could affect performance.

To ensure cooling towers fit your application, manufacturers offer a variety of materials and sizes. Cooling towers can be constructed using reinforced glass like fiberglass, stainless steel, ceramic, plastic, and aluminum. Fiberglass is particularly suitable for outdoor applications due to its durability in harsh weather, lightweight nature, and corrosion resistance. Cooling towers can range in size from small rooftop units to structures as large as 400 feet. In moist, high-temperature environments, manufacturers will incorporate fans into the design. Fans are crucial in these settings as they reduce the likelihood of microorganism growth by circulating water and air throughout the system.

Safety and Compliance Standards

The highest quality assurance for your cooling tower comes from its certification or approval according to the standards of key organizations. Two prominent ones are ASME (The American Society of Mechanical Engineers) and CTI (Cooling Technology Institute). Both associations provide standards and guidelines for the performance and safety testing of cooling towers. Additionally, in the United States, cooling towers must comply with EPA (Environmental Protection Agency) regulations. Under the Clean Air Act Amendments of 1990, the EPA enforces rules aimed at reducing emissions from industrial cooling towers.

Beyond certifications and recommendations from ASME, CTI, and the EPA, your cooling tower should also adhere to the standard requirements of your specific industry, whether those are FDA standards, Mil-Specs, or others. If your cooling tower uses combustible materials or poses any fire risk, it must meet the NFPA (National Fire Protection Association) 214 standards.

Regularly checking your cooling tower for performance, efficiency, and general safety is crucial. For example, if your system uses evaporative cooling, both ASME and CTI recommend measuring your tower’s effectiveness using wet bulb temperatures. The wet bulb temperature is the lowest temperature to which water in your system can be cooled, measured with a psychrometer. By measuring the wet bulb temperature of air entering the intake port, you can assess your system’s efficiency and calculate the rate of heat transfer through water evaporation. Detailed guidelines for performing these measurements are available from ASME and CTI.

Things to Consider

For optimal results, it’s essential to collaborate with an experienced, trustworthy, and intuitive cooling tower manufacturer. To help you get started, we’ve compiled a list of industry-leading, vetted custom cooling tower manufacturers. Their information, including interaction profiles, is integrated throughout these informational paragraphs.

To determine which manufacturer is best for you, begin by compiling a list of your specifications, questions, and concerns. Make sure to include your timeline, budget, standard requirements, delivery preferences, installation support needs, and the level of post-installation/delivery support you require. Once you have your list, start your search for a supplier. Review the manufacturers we have listed on this page, cross-referencing your specifications frequently. Identify three or four manufacturers who seem to meet your needs and reach out to each of them to discuss your requirements. Pay attention to their general demeanor, as customer service is important. After your conversations, compare and contrast your interactions, and select the cooling tower manufacturer that best suits your needs.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services