Chillers cooling towers are an essential component of modern air conditioning systems and industrial processes. These systems work by removing heat from water or air and transferring it to the surrounding environment. Read More…

Cooling Tower Systems has manufactured various models of cooling tower systems and related equipment for over 40 years, with five different models in production- one to meet every need for businesses of all sizes. We are the oldest, full-service fiberglass water cooling tower manufacturer in business today. All CTS cooling towers are designed, engineered and tested by our own factory research and ...

As a leader in the industry, we have become competitive in all types of cooling tower projects of any size and design. We are constantly developing newer methods to serve the growing needs in the industry, and our efforts have led us to become a highly competitive, full-service engineering, design, and repair contractor. Our emphasis on performance and low maintenance continues to give STAR the...

Since 2004 Composite Cooling Solutions (CCS) has been a supplier for cooling tower solutions. Though CCS was officially created in 2004, our staffs experience in the field goes back over a century and a half. We specialize in creating concrete cooling towers with both counterflow and crossflow configurations. With our extensive background in the industry and our growing number of cooling tower...

At Cold Shot Chillers, we create a number of chilling systems, including cooling towers. Our products are designed for durability and cost effectiveness. Our engineers can easily custom build any machine to fit the needs of a particular application.

More Chillers Cooling Tower Manufacturers

Components of Chillers Cooling Towers

Common components of chillers cooling towers include condenser coils, evaporator coils, compressors, water pumps, fans, water treatment systems, and control systems. The process of heat exchange between water and air begins with the evaporator coils, which contain a refrigerant that absorbs heat from the water. The refrigerant is then compressed by the compressor and transferred to the condenser coils, where the heat is released into the surrounding air or water. Water pumps circulate the water through the system, and fans move air across the condenser coils to facilitate heat transfer. Water treatment systems ensure that the water used in the system is free from impurities that could reduce its efficiency. Control systems regulate the operation of the various components to maintain optimal performance.

Variations of Chillers Cooling Towers

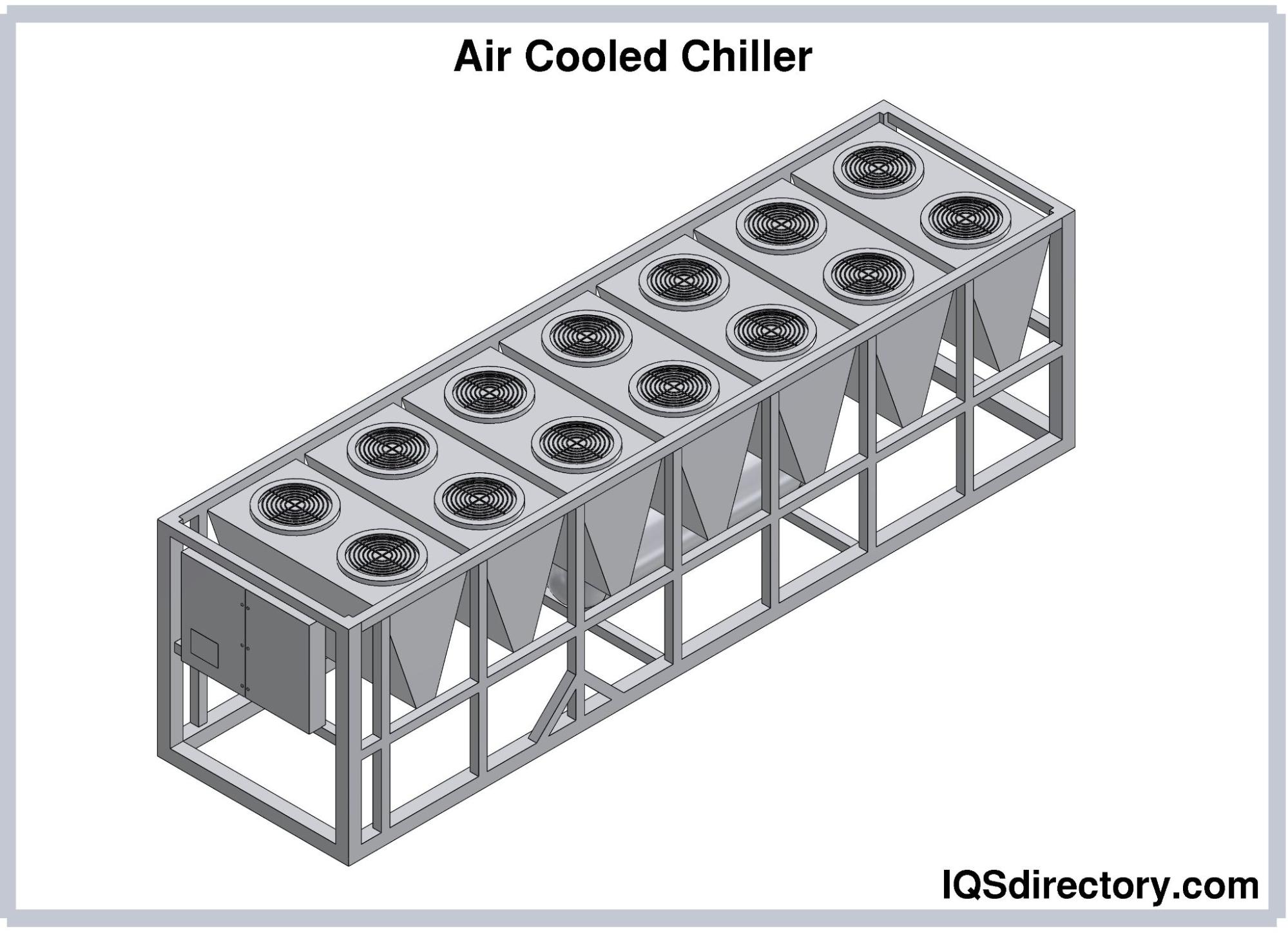

There are variations in the design or components of chillers cooling towers to suit different applications. Open circuit cooling towers are used in large industrial processes that require large amounts of water for cooling. Closed circuit cooling towers, on the other hand, use a separate heat exchanger to transfer heat from the water to the air, reducing the risk of contamination. Single stage chillers are used in applications where temperature control is not critical, while multistage chillers are used in situations where there is a need for precise temperature control. Air-cooled chillers are used in applications where water is not readily available, and where noise is not a concern. Water-cooled chillers, on the other hand, are used in applications where water is readily available and where noise is a concern. Absorption chillers are used in situations where waste heat is available and where electricity is expensive.

Considerations Regarding Chillers Cooling Towers

While chillers cooling towers are a valuable component of air conditioning systems and industrial processes, there are some considerations associated with their use. One of the most significant concerns is the potential for Legionella growth. To prevent Legionella growth, water treatment systems must be in place to maintain proper water chemistry and cleanliness. Routine maintenance, including cleaning and disinfecting, is also necessary. Another concern is noise pollution. Chillers cooling towers can produce a significant amount of noise, which can be problematic in residential or urban environments. Proper design and installation can minimize the noise produced by these systems. Initial costs can also be a drawback. Chillers cooling towers are typically more expensive to install than other cooling systems, but their energy efficiency and longer lifespan can offset these costs over time.

Benefits of Chillers Cooling Towers

Despite these considerations, chillers cooling towers offer many benefits that make them a popular choice for cooling applications. One significant advantage is their energy efficiency. Chillers cooling towers use less energy than traditional air conditioning systems, reducing operating costs and environmental impact. Additionally, these systems have a longer lifespan than other cooling systems, reducing the need for replacement or repairs. Another benefit is their ability to provide precise temperature control. Multistage chillers can maintain precise temperatures, making them ideal for applications where precise temperature control is required.

Chillers cooling towers also have a reduced environmental impact. They use less energy and have a smaller carbon footprint than traditional air conditioning systems, making them a more environmentally friendly option. In addition, chillers cooling towers offer the benefits of scalability, customization, and flexibility for business and others looking at options to serve their cooling needs.

Applications of Chillers Cooling Towers

Chillers cooling towers have a wide range of applications, including commercial and residential air conditioning, food processing and storage, pharmaceuticals manufacturing, petrochemical processing, data centers, hospitals and medical facilities, power generation, and industrial processes such as steel production, chemical manufacturing, and paper production. In commercial and residential air conditioning, chillers cooling towers provide efficient cooling to large buildings, reducing energy costs and improving indoor air quality. In the food processing and storage industry, chillers cooling towers help to preserve food by maintaining appropriate temperatures. In pharmaceuticals manufacturing, chillers cooling towers are essential for maintaining the integrity of drugs and vaccines. In data centers, chillers cooling towers help to prevent equipment overheating, reducing the risk of downtime. In hospitals and medical facilities, chillers cooling towers provide critical cooling for medical equipment and maintaining sterile environments. In power generation, chillers cooling towers are used to cool the water used in the power generation process. In industrial processes such as steel production, chemical manufacturing, and paper production, chillers cooling towers are essential for maintaining appropriate temperatures and reducing energy costs.

Choosing the Right Chillers Cooling Tower Manufacturer

To ensure you have the most positive outcome when purchasing a chillers cooling tower from a chillers cooling tower manufacturer, it is important to compare several companies using our directory of chillers cooling tower manufacturers. Each chillers cooling tower manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each chillers cooling tower business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple chillers cooling tower companies with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services