Frigosystem-Corema

Frigosystem-CoremaRequest A Quote

Columbus, OH | 614-601-8037http://www.frigosystem.it/en/dry-coolers-en

The DRY COOLERS have the advantage of being able to operate without water consumption eliminating all the typical problems of traditional cooling towers because the system works in closed circuit (no air-water contact), without losing control in efficiency. All DC systems can be included into existing systems and controlled by a new generation microprocessor that also allows the insertion of a modulating three-way valve on the system for further savings. As closed circuit systems, dry coolers deliver several benefits compared to wet cooling towers, including lower initial costs and maintenance (no tank to maintain), improved system reliability, and increased up time. Being equipped with an evaporative pre-cooling, dry coolers offer the efficiency which is, as for wet-type cooling towers, only limited by wet bulb temperature. In light of the above, the most significant factor in the choice between open-circuit cooling tower and dry cooler remains the system capacity. Continuous introduction of new efficient technologies such as microchannel heat exchangers, EC fans, intelligent controls, and others let consider dry coolers as an effective part of new environmental friendly thermal systems. As a summary, these are the advantages:

Boilers

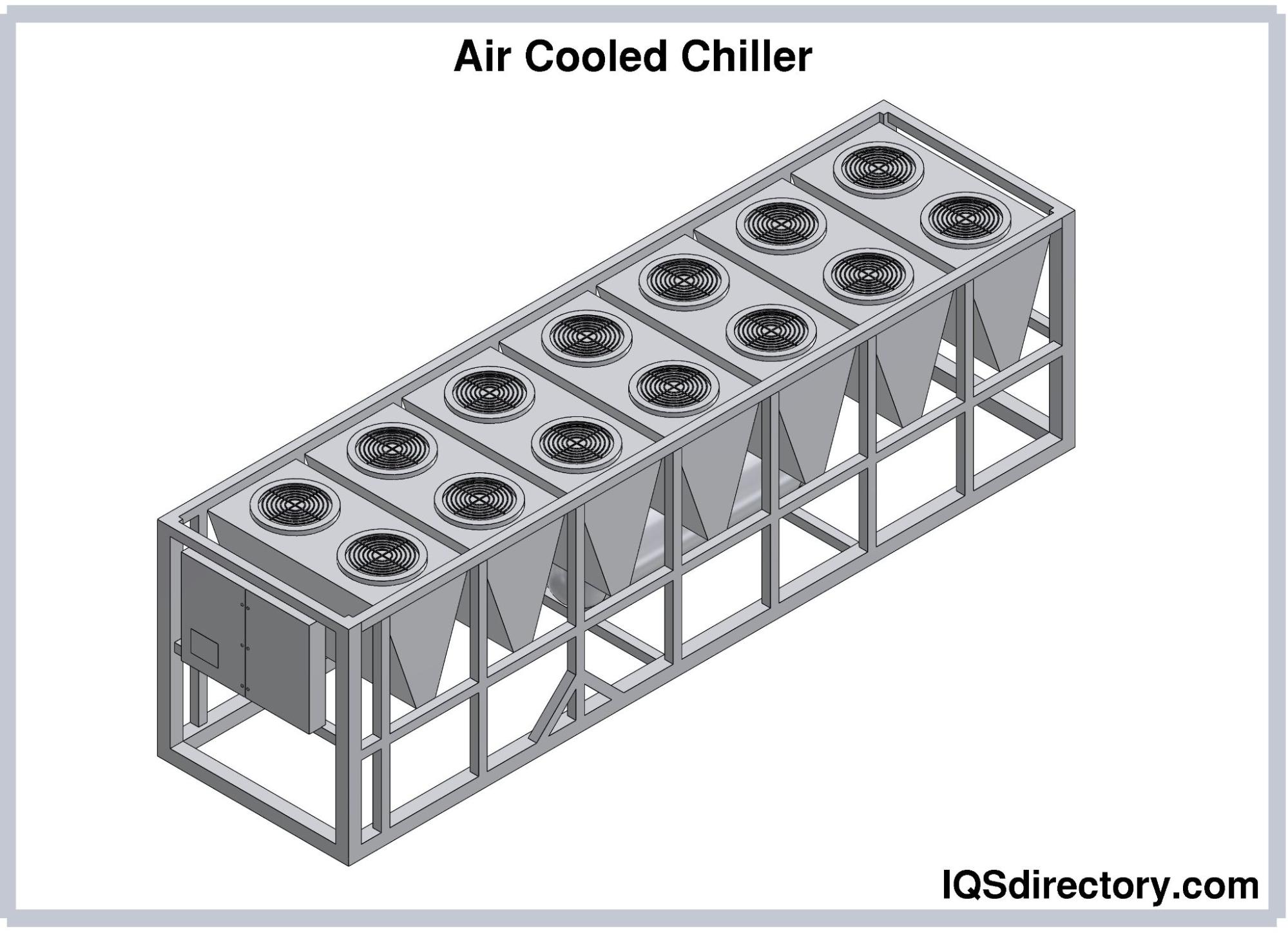

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services